Главная страница » Services » Engineering Research Center » Engineering topogeological surveys

Главная страница » Services » Engineering Research Center » Engineering topogeological surveys

Drilling works are carried out during geotechical surveys to study the lithological section and hydrogeological conditions, take rock samples and water samples, conduct aquifer testing and field studies of the state and properties of rocks. The drilling activities result in boreholes varying in features and classified by depth.

The boreholes are divided by their purpose:

sounding;

exploration (may be technical);

hydrogeological;

test.

The boreholes are divided by their depth:

shallow (up to 10 m);

short (from 10 to 30 m);

medium (from 30 to 100 m);

deep (more than 100 m)

Drill rig КB 30/150 is fitted with a centrifugal pump with a pressure of 13 bar or an auger-type pump with a pressure of 18 bar to drill boreholes to a depth of up to 150 meters. Simultaneous casing methods such as Symmetrix and Duplex can be used for КB 30/150.

Designed specifically for drilling of holes for geothermal probes and water wells deeper than 100 m.

A drilling method depends on a geological structure, survey stage, purpose of a borehole, and assigned geotechnical task. The selected drilling method shall ensure obtainment of required geotechnical data and high efficiency of drilling. The most reliable geotechnical data may be obtained by drilling methods that provide rock samples in the form of a column formed as a result of the ring bottom hole. One of these methods includes core drilling, which is widespread in geotechnical surveys. Core drilling extracts rock from the borehole in the form of a core by means of a coring tube fitted with a drill bit.

Application of core drilling systems with retractable core barrel allows increasing drilling productivity by 1.5-2 times and core recovery up to 90-100%.

The process of borehole drilling with the use of retractable core barrel has the following sequence:

Preparation of the drilling string,

Borehole drilling

One of the types of engineering geological works is drilling of boreholes and sinking of pits.

Drilling is necessary to determine the geological structure of the site and soil composition, to determine the presence or absence of groundwater, to select soil samples for analyzing properties, and to conduct field studies of the obtained properties.

The following types of borehole drilling are used in engineering geologic investigations:

Percussion-channel

Column drilling

Vibratory

Drilling can be carried out both by machine method and manually. Nowadays, machine drilling is more often carried out, especially for large-scale construction.

The following methods of monolith sampling are used in the surveying practice: hammering (by repeated blows and one blow), punching, drilling, vibrating, and rotating. The method of driving the test tubes largely depends on the type of machines used to drill the boreholes.

Monoliths samples of clayey soils of stiff and low-plastic consistence are taken using thin-walled cylindrical test tubes with an outside sharpened bottom edge punched into soil at a speed of not more than 2m/min. Monoliths samples of loose sandy soils, clayey soils of high-plastic and very soft consistency, decomposed peats are taken using test tubes punched into soil at a speed of not more than 0.5 m/min.

Static and dynamic testing of the crane is carried out at the enterprise, the owner of the cranes provides a set of test weights, with the actual weight indicated on them. After testing of overhead cranes, the owner is given a test report of the crane, which indicates its serviceability or not.

Testing of hoisting cranes guarantees safe and quality work at the enterprise

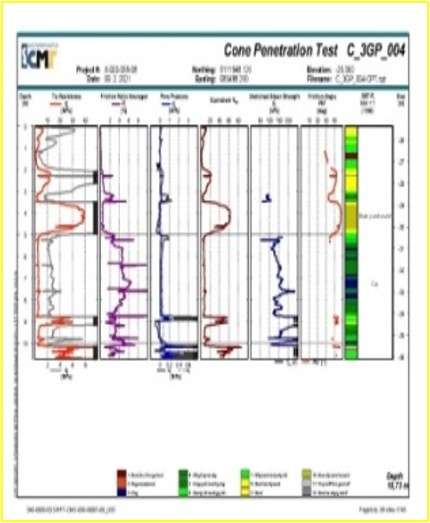

SCPTu consists in measuring the time of a share wave propagation in the ground between the surface of the terrain and the end of the probe, in which accelerometers or geophones are additionally installed. A seismic wave occurs upon impact (in the horizontal direction, a shear wave) against a steel anvil placed on the ground surface. At the moment of impact, the signal (velocity or acceleration) at the tip of the probe begins to register. By the time the seismic wave reaches the depth at which the probe is located, the average speed of shear wave propagation in the medium is calculated. By performing test, for example, at intervals of 1 m and comparing the results of measurements at adjacent levels, it is possible to determine the speed of wave propagation in a given layer of 1 m thickness.

Well testing in the process of drilling allows the following: to constantly monitor the progress and all details of sinking by the methodical party, to choose and apply the formulation of washing fluid that preserves the original filtration properties of the passed reservoirs; to set its specific gravity, so as not only not to interrupt flows, but even to create the best conditions for their excitation; to conduct mechanical logging; to select, systematize in a column and study the cuttings and core coming from the bottomhole; to conduct all kinds of electrometric studies; to carry out all kinds of electrometric studies; to carry out the following tests

Standard Penetration Test is one of the methods of investigating soil properties in preparation for construction or other earthworks. It is applied to determine mechanical and physical properties of soils, which determine their behavior under the load from the erected structures, which helps to avoid errors in the process of developing design documents and the subsequent arrangement of supporting foundations. In contrast to Cone Penetration Tests, the Standard Penetration Test method is based on the use of shock or shock-vibration loads.

Field soil tests are part of the complex geotechnical survey.

The purpose of the field soil tests (together with lab and (or) geophysical test) is to:

·Study soil masses, dissect the geological cross section, delineate the seams and interlayers of weak or other soils,

·Determine physical, deformation and strength properties of soils in natural conditions,

·Assess a spatial variability of soil properties,

·Asses a probability of piles driving into the soil and bearing capacity of the piles,

·Conduct stationary observations of changes in the physical and mechanical properties of reclaimed and bulk soils over time,

·Determine dynamic stability of water-saturated soils,

The main field soil tests are:

·CPT & SPT;

·ball stamp, pressuremeter, etc. (Direct shear test, rotational shear test, progressive shear test, reference pile test)

Stamp tests are used to evaluate the stress-strain behaviour of soil, as well as the quality of compaction, and are performed for shallow foundations. This test may be performed for all types of dispersed (loose) soils, embankments and gravel, but is not usually used for very soft and fine-grained soils.

•Preparation of terms of reference

•Obtaining optimal technical conditions for connecting the facility to utility system

•Obtaining an Architectural and Planning assignment in the Department of Architecture and Urban Development

•Carrying out of public hearings

•Approval of motor road projects with the Policy Department

•Approval of projects in Water resources inspection

•Approval of design solutions in the Department of Industrial Safety

•Development and expertise of Declarations of industrial safety with obtainment of registration numbers

•Carrying out of Energy expertise

•Preparation of traffic diagram with indication of material delivery points.

•Approval of a Plot plan with the Chief Architect

• Analysis of detailed documentation for compliance with standards in the field of architecture and construction, environmental protection and sanitary-epidemiological welfare

•Uploading of design documentation to the web-portal of Comprehensive extradepartmental expertise

•Work with experts, solving the arising issues, approval of technical and economic indicators

•Obtaining a positive expertise conclusion

•Obtaining an environmental emission permit

•Obtaining a coupon for commencement of construction and assembly works.